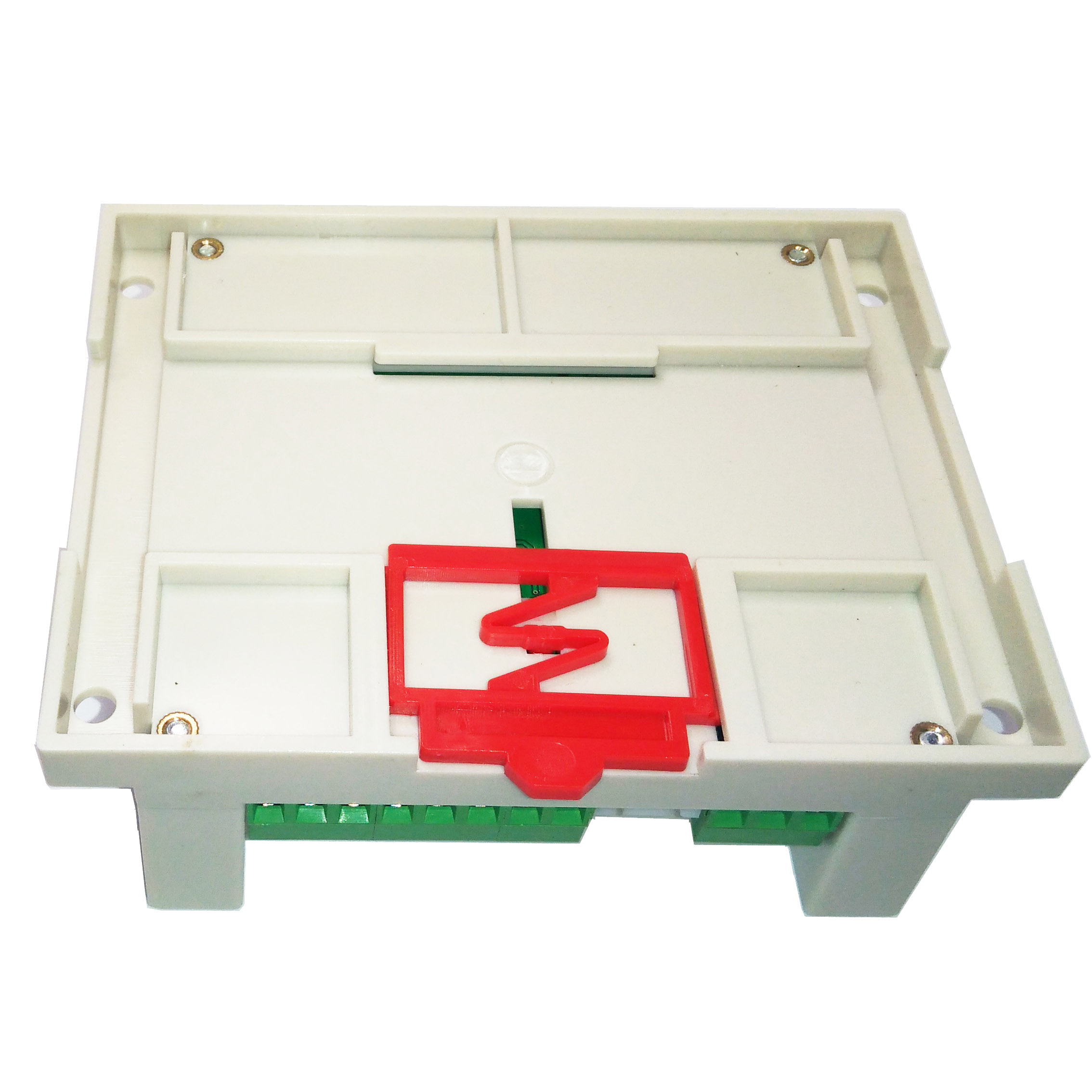

The second portion is the indexer or PLC card.

Motion pulse motor Pc#

It can be as sophisticated as a PC or PLC or as simple as an operator push button.

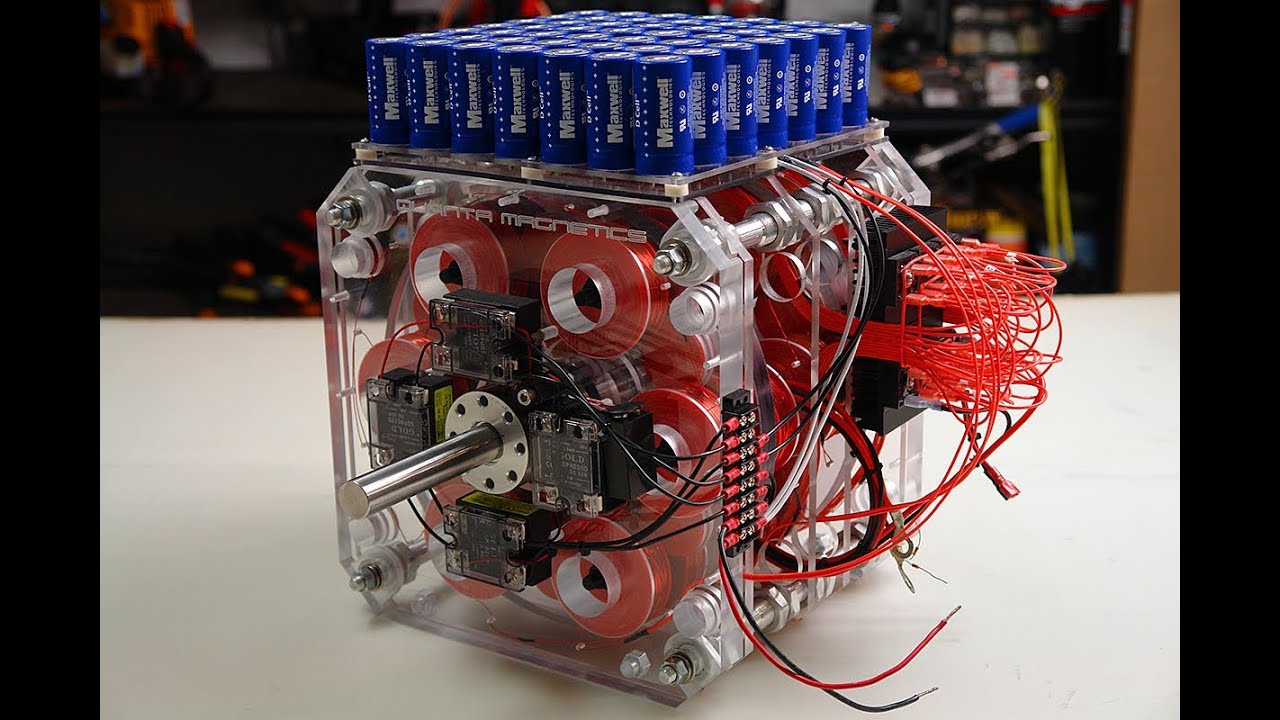

It might raise an elevator or advance a conveyor. The computer not only control the stepper motor system but will also control the rest of the machine. The first component is the computer or PLC. Each component's performance will have an effect on the others. All of these parts must be present in one form or another. The diagram below shows a typical stepper motor based system. For this reason stepper motors are ideal for short, quick moves. They have low rotor inertia that can get up to speed quickly. Stepper motors can respond and accelerate quickly. If the same motor travels one million steps, it will travel 1,800,000° ± 0.05°. When a standard stepper motor travels one step it will go 1.8° ± 0.05°. The remarkable feature of steps motors, though, is that this error does not accumulate from step to step. ORIENTAL MOTOR's standard stepper motors have an accuracy of ± 3 arc minutes (0.05°). Stepper motors are not perfect, there are always some little inaccuracies. One of the most remarkable features of stepper motors is their ability to position very accurately. You merely need to design a circuit to output pulses or use one of ORIENTAL MOTOR's pulse generators.

Motion pulse motor drivers#

Most drivers are looking for 5 volt pulses which just so happen to be the voltage level of most integrated circuits. The motor will spin at a rate that is equal to the frequency of those same pulses. The number of pulses the motor turns is equal to the number of pulses fed into the driver. Stepper motors are controlled by a driver, which sends the pulses into the motor causing it to turn. Stepper motors are so named because each pulse of electricity turns the motor one step. Not only does a stepper motor convert electrical power into rotation, but it can be very accurately controlled in terms of how far it will rotate and how fast. Electric motors convert electricity into motion. Stepper motors convert electricity into rotation. For more information about Nippon Pulse’s quality products, visit or call 1-54.Every motor converts power. We provide a wide array of motion control solutions to meet your needs, including industry-leading stepper motors, the innovative Linear Shaft Motor, controllers and drivers. Nippon Pulse is a global manufacturer and Tier 1 supplier of precision motion control products for original equipment manufacturers. is an American subsidiary of Tokyo-based Nippon Pulse Motor Co., Ltd.

Motion pulse motor manuals#

Copies of our catalog and the L250xS series datasheet – which contains specifications on both the L250SSS and the other 25mm small-forcer options – can be found on the Manuals & Literature page of our website. If you can’t find one that meets your specifications, we would love to work with you on a custom design.įor more information about the L250SSS or any of our other Linear Shaft Motors, contact or call 54 to speak to application engineers. Nippon Pulse has the largest selection of linear motor products available, with more than 10,000 standard configurations. Both the L250SSS and the other motors in the SS series are ideal for life sciences and industrial applications in which multiple forcers are required to travel along a single shaft. The SS series motors are available in 25, 32 and 35mm shaft diameter sizes, and with single, double, triple and quadruple winding options. The L250SSS motor is part of Nippon Pulse’s existing SS series of Linear Shaft Motors, which features small forcers and stack-lengths for high-density applications. Its maximum usable stroke reaches to more than two meters in length. It is a 25-mm-diameter linear servo motor with a single winding and our smallest available forcer – only 30mm in length, and with higher force than competing off-the-shelf motors. now sells one of the smallest available linear motors for high-density applications - the L250SSS Linear Shaft Motor.

0 kommentar(er)

0 kommentar(er)